Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

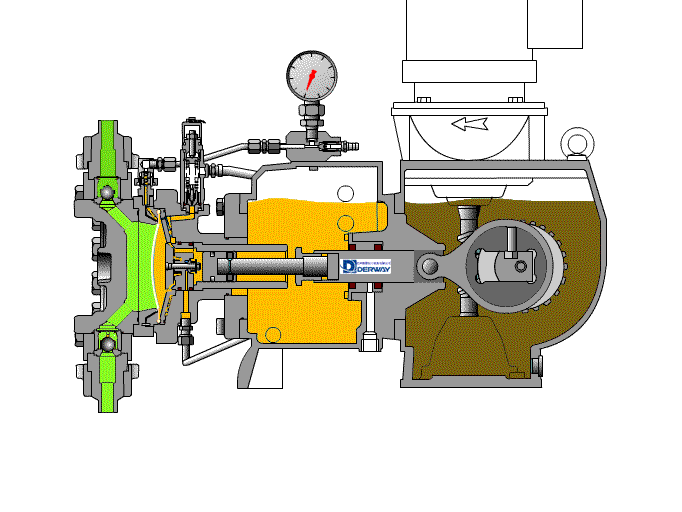

Mechanical Diaphragm Dosing Pump

Hydraulic Diaphragm Metering Pump

In the Diaphragm Metering Pump, in order to make the diaphragm in the diaphragm Metering Pump work normally, the volume of the hydraulic oil in the hydraulic chamber of the metering pump must remain unchanged; so that the volume formed by the diaphragm reciprocating movement is always equal to the travel volume of the plunger, thus keeping the flow of the diaphragm metering pump unchanged.

However, in the actual use of the metering pump,as the plunger seal produce leakage phenomenon sometimes, while the leakage may have gas into the hydraulic cavity.If the oil replenishment is too much or the pressure of the discharge pipe rises unexpectedly, the volume of the fluid in the hydraulic cavity will change, which affects the instability of the metering pump flow, thus reducing the measurement accuracy of the metering pump.

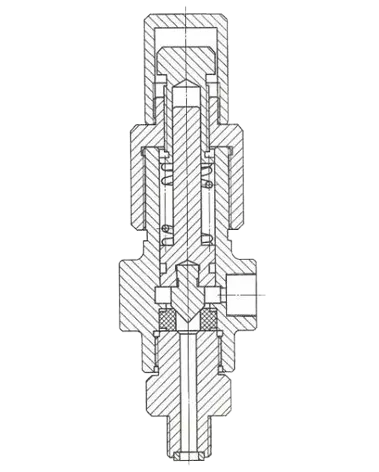

Therefore, in order to solve the above problems, each metering pump adopts the so-called three-valve device, which actually refers to the combination of three functions such as compensation valve, relief valve and safety valve which supporting the hydraulic cavity.According to its principle of action, they are also called automatic compensation three-valve mechanism.

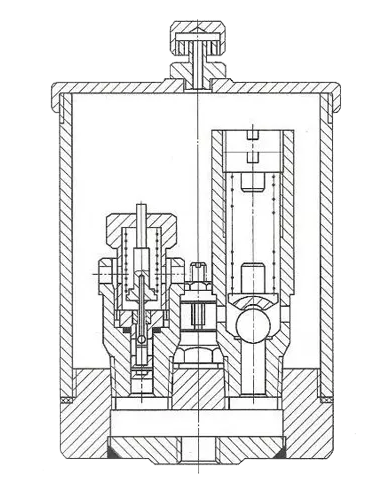

The automatic compensation three-valve device is widely used in diaphragm metering pumps, especially with the highly required of suction height,we have to use this device.It consists of three separate valves (relief, discharge, and compensation valves), as shown.

1.

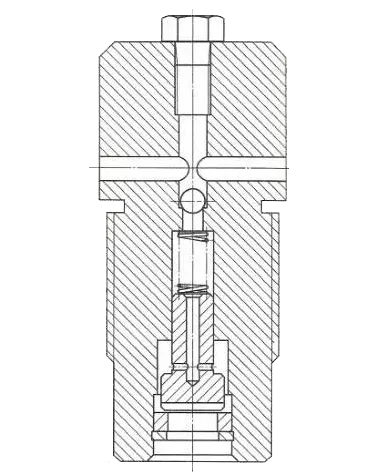

Measurement pump compensation valve

During the long time running of metering pump,as the leakage of the working medium at the piston seal increases, the amount of oil in the hydraulic chamber will gradually decrease.When the suction stroke and the diaphragm has reached the rear limit plate, and the plunger has not reached the rear dead point, an instantaneous vacuum will be formed in the hydraulic chamber, which will reduce the flow rate. Therefore, a compensation valve needs to be set to automatically compensate for the amount of oil lost in the hydraulic cavity when an instantaneous vacuum occurs.

The three-valve device for forced compensation connects the filling film and the hydraulic cavity whenever the cylinder reaches the dead point, and whether the filling is determined by the pressure of both.The compulsory compensation three valves is also set at the top of the hydraulic cavity, which has the function of discharging while filling the oil.

2.

Metering Pump Air Relive Valve

Since the plunger seal is impossible to completely avoid gas entry. Other situations such as refueling when the gas may also enter the hydraulic cavity, after the formation of air bags will greatly affect the accuracy of the measurement.The vent valve therefore needs to be set up.The discharge valve shall be set at the top of the hydraulic cavity to facilitate gas discharge.

3.

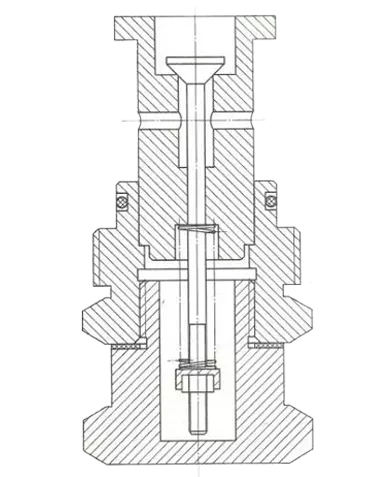

Metering Pump Safety Valve

The function of the metering pump Safety Valve is to ensure that the pressure in the hydraulic cavity is not abnormal to protect the diaphragm.

When the hydraulic oil in the hydraulic cavity exceeds the limit and the end of the front limit plate before the diaphragm reaches, the cylinder plug will still move forward and the pressure in the hydraulic chamber will rise sharply, and the safety valve of the metering pump shall be opened quickly.

At the same time, when the safety valve in the discharge line pressure is not normally increased, the metering pump safety valve can also protect the metering pump from damage.The opening pressure of the metering pump relief valve should be easily finely enough and accurately adjusted.

LET'S GET IN TOUCH

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.