Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Mechanical Diaphragm Dosing Pump

Hydraulic Diaphragm Metering Pump

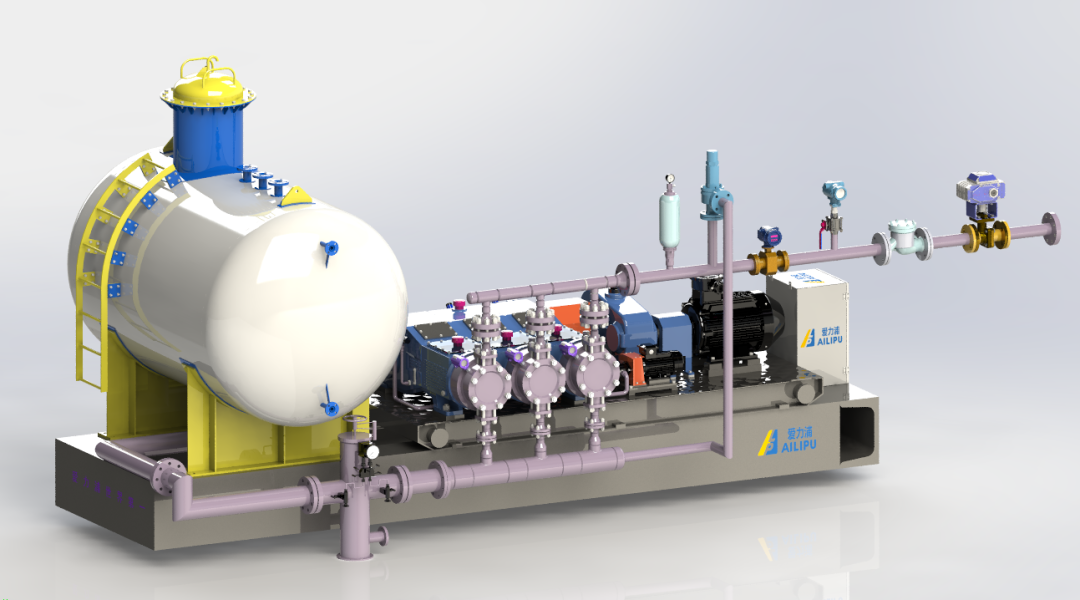

The diaphragm pump is developed by AILIPU based on years of experience in reciprocating pump. It is composed of power end, plunger combination, and hydraulic end, mainly used for the transportation of oilfield sewage and other media. The liquid end of the pump can also deliver highly corrosive acid, alkali and other media after replacing the materials.

What are the characteristics of the reciprocating three-cylinder plunger high-pressure diaphragm pump?

01 The diaphragm completely separates the delivery medium from the hydraulic oil to ensure zero leakage. It is suitable for corrosive, highly toxic, and high precision requirements.

02 The exhaust valve automatically releases the air in the hydraulic chamber.

03 The compensation valve can timely supplement the hydraulic oil in the hydraulic cavity, maintain the stable oil quantity of the hydraulic cavity, and ensure the measurement accuracy of the pump.

04 Hydraulic driven oil road shall be fully closed to prevent impurities and personnel operation damage.

05 Double diaphragm pump: with all the advantages of the diaphragm pump, one diaphragm is damaged, the other can continue to work, and send an alarm signal, suitable for toxic, flammable, explosive and strong corrosive dangerous media.

06 Hydraulic metal diaphragm pump head for high temperature and high pressure occasions with a maximum temperature of 451℃ and a pressure of up to 70MPa.

What is the innovation point of the reciprocating three-cylinder plunger high-pressure diaphragm pump?

01 For higher measurement accuracy, a frequency conversion motor is used to provide primary power. The frequency conversion motor has the characteristics of short response time and convenient adjustment, which can detect various sensor signals and quickly change the rotation speed of the motor.

02 The application of the fixed stroke limit oil filling mechanism not only ensures the filling of the hydraulic oil in the hydraulic cavity, but also avoids excessive oil replenishment, so as to make the force balance on both sides of the diaphragm, improve the service life of the diaphragm, and has vacuum absorption performance.

03 Three plunger pumps are selected to reduce flow pulsation and water hammer phenomena in the system.

04 The crankshaft is the core drive part of the three-cylinder process diaphragm pump. Because of the wide box body, the crankshaft adds two support necks in the middle of the ordinary three crank pin crankshaft, which is the three crank pin and four support crankshaft.

LET'S GET IN TOUCH

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.